Laws and standards

The monitoring of containers and pipes for leaks is regulated by law within the EU. Various regulations apply at international and national level.

- The European standard EN 13160 defines the requirements for leak detectors in Europe and describes various systems.

- The Water Management Act (Wasserhaushaltsgesetz – WHG), the federal Ordinance on Facilities for Handling Substances Hazardous to Water (Verordnung über Anlagen zum Umgang mit wassergefährdenden Stoffen – AwSV), and the Ordinance on the Determination of the Suitability of Construction Materials and Construction Types under the Water Management Act (Wasserhaushaltsgesetz – WHG) through Proof in Accordance with the Sample Construction Regulations (Verordnung zur Feststellung der wasserrechtlichen Eignung von Bauprodukten und Bauarten durch Nachweise nach der Musterbauordnung – WasBauPVO) stipulate the regulations in Germany.

EN 13160

European standard for leak detection technology

EN 13160 defines the property requirements for various leak detection systems in five classes. Class I requires/provides the highest safety standard and best environmental protection, and class V the lowest safety standard and worst or no environmental protection. Each European country decides at national level which classes are permitted or banned.

In Germany, underground systems must always be Class I systems and systems above ground can also be Class II.

EN 13160 classes

Systems in this class indicate leaks above or below the liquid level in a double-walled system. They are constructed with safety in mind and indicate leaks before the stored/conveyed product can enter the environment (e.g. overpressure or vacuum systems). (Definition according to EN standard)

Examples:

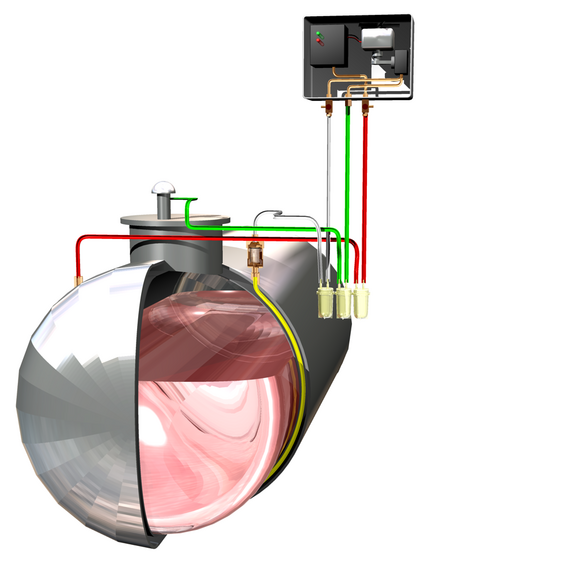

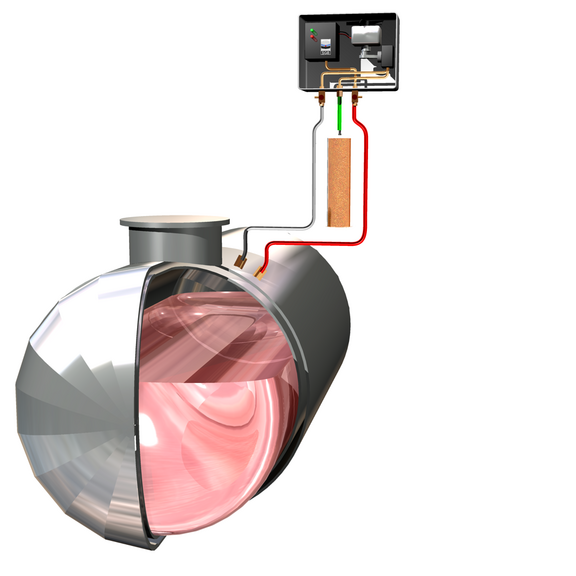

Monitoring of a heating oil tank with a leak protection lining and suction line to the low point of the interstitial space by a vacuum leak detector

Tank monitoring at a filling station with a pressure leak detector (leak detection medium: dried air)

Systems in this class indicate a leak above and below the liquid level in a double-walled system with a possibility of the leak detection liquid entering the environment. (Definition according to EN standard)

Class III systems indicate a leak in the tank or pipe below the liquid level. These systems are based on liquid and/or gas sensors installed in a leak chamber or interstitial space. The stored/conveyed product could enter the environment. (Definition according to EN standard)

Systems in this class indicate a specified value for changes in the tank with a certain probability (e.g. leaks into or out of the tank). If there is a leak, the stored product is highly likely to enter the environment.

There are several classes:

IV a Dynamic systems also indicate leaks in the connected pipe by way of comparison, and

IV b Static tank content leak detection systems and leak detection systems with static short-term indicator only show leaks in the tank.

Systems in this class are able to indicate loss of liquid in tanks or pipes below the liquid level. Before the leak is indicated, the product enters the environment (e.g. through sensors in the monitoring chambers). (Definition according to EN standard)

Comparison of EN systems/classes

National regulations in Germany

WHG, AwSV and WasBauPVO/BauPAVO

The Water Management Act (Wasserhaushaltsgesetz – WHG) defines aspects such as the principle of concern that water is a resource worth protecting: “The purpose of this law is to protect the bodies of water as part of the ecosystem, as the basis of human life, as the habitat for animals and plants, and as exploitable resource through sustainable water resource management.” (Section 1, WHG) From this follows that:

“(1) Facilities for storing, filling, producing and treating substances hazardous to water, as well as facilities for using substances hazardous to water in the commercial sector and in public facilities, must be designed and constructed, maintained, operated and shut down in such a way that there is no risk of adverse changes to the properties of water bodies.” (Section 62 Requirements for handling substances hazardous to water, WHG)

The federal Ordinance on Facilities for Handling Substances Hazardous to Water (Verordnung über Anlagen zum Umgang mit wassergefährdenden Stoffen – AwSV) stipulates how this is to be achieved:

- Underground: Double-walled and leak-monitored containers and pipes (only exception: suction lines)

- Aboveground: Double-walled and leak-monitored containers without collecting tubs, etc.; with a leak detection probe, if necessary, for single-walled containers in the collecting chamber

All work must be performed by technical service companies (Section 45, AwSV). This means that “underground systems and aboveground systems for handling liquid substances hazardous to water, consumer’s heating oil installations, [...], may only be installed, cleaned internally, repaired and decommissioned by technical service companies in accordance with Section 62.”

The Ordinance on the Determination of the Suitability of Construction Materials and Construction Types under the Water Management Act Through Proof in Accordance with the Sample Construction Regulation (Verordnung zur Feststellung der wasserrechtlichen Eignung von Bauprodukten und Bauarten durch Nachweise nach der Musterbauordnung – WasBauPVO ) or the Ordinance on Construction Materials and Construction Types, Ordinance on Regulations for Construction Products and Construction Types under the Construction Management Act (Bauprodukte- und Bauartenverordnung, Verordnung über bauordnungsrechtliche Regelungen für Bauprodukte und Bauarten – BauPAVO )(only in NRW and MV) defines construction products for which a proof of suitability under the Water Management Actmust be present: such as safety devices such as leakage detectors.

The proof of suitability under the Water Management Act is provided through:

- General technical approvals (today only for special applications, system approvals)

- CE marking and declarations of performance in regard to EN 13160 (MVVTB) with a test by an accredited test laboratory

- Conformity marking with manufacturer’s declaration of performance process in regard to EN 13160 (MVVTB) with a test by a recognized testing, monitoring and certification body